Maintenance Guidelines for Permeable Interlocking Concrete Pavement Systems

The sustainability of pavement infrastructure is paramount to ensuring viable transportation of people and goods. With the increasing size of roadway networks and increasing commercial vehicle loading, the investment required to maintaining the roadway network is increasing. Preventive maintenance treatments reduce the risk of premature deterioration, slow the progression of defects, and cost-effectively extend the life of the pavement.

The key for cost-effective preventive maintenance is applying the appropriate treatment at the right time. The objective of a preventative maintenance plan is to identify those sections that would benefit most from preventive maintenance, make the identification in a timely manner, and select and apply the most beneficial treatment.

This article provides operation and maintenance guidance to ensure that permeable pavements function properly by providing stormwater infiltration and structural support for the anticipated traffic loading. It provides a background on the need for pavement preservation as well as specific performance criteria for the cost-effective maintenance of permeable pavements. Details of specific processes and procedures to ensure the long-term permeability of the pavement, as well as procedures to evaluate the performance of the permeable pavement surface, are provided. This includes procedures to check the permeability of the pavement surface; the stability of the pavement, including edge restraints; localized deficiencies such as missing pavers, rutting, and cracked pavers, along with their extent and severity; and procedures to rectify any deficiencies. The article also provides recommendations for an annual monitoring program and maintenance plan, and detailed guidance for the effective maintenance of the pavement.

Permeable Interlocking Concrete Pavement

Permeable interlocking concrete pavements (PICPs) have been used in North America since the early 1990s. The pavement consists of specially constructed pavers with gaps between the units. Instead of the traditional sand in the joints, an open graded stone chip material is used. This provides for friction between the pavers while allowing water to pass more freely through the joints into the underlying reservoir layers. The permeable joint space between the pavers is about 8 to 10% of the paved surface. The pavers are laid on a 50-centimeter bedding layer of open graded chip aggregate. The interlock of the pavers provides their strength under loading. Below the pavers, a typically 10-centimeter base layer and variable-thickness reservoir sub-base is used to accommodate the hydrologic goals for the pavement.

These facilities can support vehicular traffic while minimizing stormwater runoff and recharging groundwater supplies. In general, initial surface infiltration rates exceed 200 centimeters per hour (USEPA 2010), which provides effective passage for rainfall and adjacent runoff into the sub-base reservoir. Design pollutant removal efficiencies are on the order of 85% for total suspended solids (TSS), 35% for total phosphorus, and 30% for total nitrogen (NCDENR 2012).

The Interlocking Concrete Pavement institute (ICPI) has published a PICP guide that provides information on design, specifications, construction, and maintenance for permeable concrete pavements. The American Society for Testing Materials (ASTM) has published a standard for the condition evaluation of conventional interlocking concrete pavements (ASTM E2840-11). The American Society of Civil Engineers (ASCE) through the Transportation and Development Institute (T&DI) is planning the publication of a Standard Guideline for the Design, Construction, and Maintenance of Permeable Interlocking Concrete Pavement in 2015.

Because of the open nature of the surfaces, permeable pavements clog with sediment and debris overtime, thereby decreasing the infiltration rate. The rate of decrease depends on sources of deposited sediment. Such reductions from normal use still render a surface that can infiltrate most rain events. Gradual clogging of the surface layer can have the benefit of capturing some suspended solids that would otherwise be deposited into the sub-base and/or discharge from the underdrains. With regular maintenance, the sediment that is captured near the surface can be more readily removed than sediment that accumulates in the sub-base.

Surface Infiltration

Surface infiltration of the PICP is achieved through the surface water’s ability to infiltrate through the joints between the pavers. Reduced surface infiltration would be observed by water ponding on the surface due to clogging of the joints. The joints are typically filled with clean aggregate open graded aggregate (typically ASTM No. 8, 89, or 9 stone). Over time, the joints can become clogged with debris and sediment. To ensure that the surface infiltration remains at a functional level, monitoring of the infiltration rates should be completed. Poor surface infiltration would be considered when the infiltration rate falls below the design infiltration rate or below (25 centimeters per hour, ICPI 2011).

Secondary Drainage Features

For urban roadways, once the surface water is infiltrated through the joints, it is temporarily stored in the open graded base and sub-base reservoir layers. From these reservoir layers, the water is channelled to secondary drainage features such as subdrains, outflows, and stormdrains. These secondary drainage features need to be monitored for clogging potential and damage to ensure that the stored water can be removed.

Pavement Condition Evaluation and Maintenance Actions

To maintain the integrity of the permeable pavement and provide the necessary support for the traffic loading, the pavement needs to be monitored for signs of structural distresses that could impair the structural integrity. The pavers should be inspected for surface distresses and performance criteria. Procedures have been developed for all types of pavements to assist in identifying defects and in determining their extent and severity. These assessments allow maintenance and rehabilitation planning to cost-effectively extend the service life of the pavement and to avoid costly reconstruction. This information can also be used as a part of a pavement inspection program to determine an overall condition rating for the pavement to assist in longer-term rehabilitation planning. The following sections outline typical observed distresses that may occur for permeable interlocking concrete block pavements. These include

- Surface Clogging

- Depression

- Rutting

- Faulting

- Damaged pavers

- Edge restraint damage

- Excessive joint width

- Joint filler loss

- Horizontal creep

- Additional minor distresses

Surface Clogging. Surface clogging occurs when debris and other contaminants enter the jointing material and become lodged within the permeable pavement. This will reduce the permeability of the pavement and reduce the ability to store water. It also may result in localized ponding of surface water. PICP inspections should be completed once or twice annually (preferably after a storm event). Inspection tasks should include the following:

- Document general site features (photographs).

- Note obvious sources of surface contaminants such as sediment.

- Identify any changes in adjacent land use that may impact contributing area runoff for potential sources of contaminants.

- Inspect vegetation around PICP perimeter for cover and soil stability.

- Check surface for buildup of sediment in joints. Buildup typically occurs near adjoining impervious pavements. If water ponds on the PICP and remains longer than one hour after a rainstorm, then measure the permeability of the pavement surface in accordance with the procedures outlined in ASTM C1781-13.

The results of the inspection should be documented and used to assist in updating the maintenance plan for the PICP system. The information should be used to assist in predicting future maintenance needs and be part of an overall management system for the pavement. Based on the results of the inspection, it may be appropriate to conduct remedial maintenance, particularly if the surface has not been vacuumed regularly.

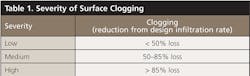

The severity levels associated with surface clogging are classified as shown in Table 1. Examples of clogging are illustrated in Figure 1.

While the severity of clogging can be estimated based on visual observation as shown in Figure 1, a new ASTM procedure (ASTM C1781-13) was released and is specifically designed to measure the surface permeability of permeable interlocking concrete pavements. The procedure requires that an infiltration ring (Figure 2) be placed on the surface. A known volume of water is placed into the ring, and the time that it takes for the water to infiltrate the pavement surface is recorded.

Areas of the pavement exhibiting medium- and high-severity clogging (or if the ASTM C1781-13 results are below 250 centimeters per hour), should be vacuumed using a full vacuum sweeper (not regenerative air). The joints should be refilled after vacuuming.

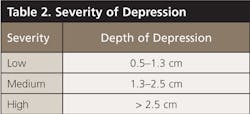

Depression. A depression of the PICP surface occurs through settlement of the underlying subgrade or granular base rather than a load-related distress. The paver surface elevations are then lower than the surrounding areas. Settlement and depressions are most common over utility cuts, near catch basins, and in areas adjacent to other roadway types. A depression is best measured using a 3-meter straight edge rather than by visual inspection. The severity of a depression is classified as shown in Table 2.

Examples of low-, medium-, and high-severity depressions are shown in Figure 3.

Pavement areas exhibiting medium- and high-severity depressions (settlement exceeding 1.3 centimeters) should be repaired to ensure smooth ride quality and reduce the risk of potential water ponding on the surface. The pavers and bedding chip in the affected areas should be removed and the exposed base leveled (with new base material added as necessary), followed by the placement of new bedding chip material and the pavers.

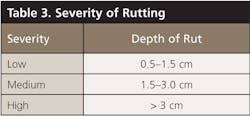

Rutting. Rutting is a type of surface depression that occurs in the wheel path. It is typically caused by settlement of the underlying subgrade or reservoir base under vehicle loading. Similarly to regular depressions, rutting should be measured using a 3-meter straight edge. The severity of rutting is classified as shown in Table 3.

Some examples of rutting are shown in Figure 4.

Pavement areas exhibiting medium- and high-severity rutting (rut depth exceeding 1.5 centimeters) should be repaired to ensure smooth ride quality and reduce the risk for potential water ponding. The pavers and bedding chip in the affected area should be removed and the exposed base leveled (with new base material added as necessary), followed by the placement of new bedding chip material and the pavers.

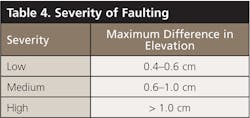

Faulting. Faulting occurs in the permeable pavement when the elevation of small areas of the surface differs or has rotated to that of adjacent blocks. Typically faulting is caused by surficial settlement of the bedding sand, poor installation, or pumping of the joint filler or bedding sand. The severity associated with faulting is defined as shown in Table 4.

Examples of pavement faulting are shown in Figure 5.

Pavement areas exhibiting medium- and high-severity faulting (maximum difference in height exceeding 0.6 centimeter) should be repaired to ensure smooth ride quality.

Damaged Paver Units. Damaged pavers are distresses observed to the actual paver units. The distresses are typically caused by load-related damage. Damage to paver units includes cracks, chips, and spalls. The severity of the damaged paver units is defined in Table 5.

Examples of damaged pavers for various severity levels are shown in Figure 6.

damaged pavers

Pavers exhibiting medium- and high-severity damage should be removed and replaced to maintain the structural load capacity of the pavement.

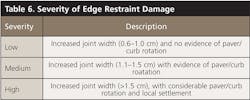

Edge Restraint Damage. Edge restraints (typically curbs) provide lateral support for the PICP. Loss of lateral support due to damage to edge restraints can result movement or rotation of the pavers or loss of joint filler and bedding course material. The severity of the paver offset is defined in Table 6.

Examples of loss edge restraint are illustrated in Figure 7.

loss of edge support

All medium- and high-severity loss of edge restraint should be repaired or replaced.

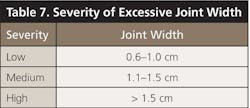

Excessive Joint Width. The joints between the pavers are critical for providing both infiltration and structural interlock. Excessive joint width is a distress that can result in the block layer becoming less stiff and can lead to overstressing of the substructure layers. It can occur from a number of factors including poor initial construction, lack of joint filler, poor edge restraint, and adjacent settlement or heave. Joint spacing between the permeable pavers is typically specified as 0.6 centimeter. As joints get wider, the individual blocks may show signs of rotation. The severity level of excessive joint width is defined as shown in Table 7.

Some examples of excessive joint width are shown in Figure 8.

excessive joint width

Pavers exhibiting medium and high excessive joint width should be removed and reset to maintain structural load capacity.

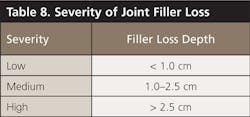

Joint Filler Loss. The joint filler in a PICP is considered essential to providing interlock and stiffness of the paver course and infiltration of the surface water. Loss of the joint filler can occur from a number of factors including excessive vacuum force during sweeping, pressure washing, and pumping under traffic loading. The severity of joint filler loss is defined as shown in Table 8.

Examples of joint filler loss are shown in Figure 9.

joint filler loss

Joint filler should be reinstated for all joints exhibiting medium- and high-severity joint filler loss.

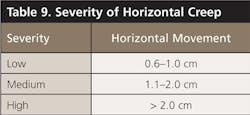

Horizontal Creep. Horizontal creep is the longitudinal displacement of the pavement caused by traffic loading. The PICP surface should have a uniform pattern. Any shifting of the joints or pattern indicates horizontal creep. The severity levels associated with horizontal creep are classified as shown in Table 9.

Areas of the pavement exhibiting medium and high severity horizontal creep should be repaired. The repair consists of removing the pavers and bedding material in the affected area. The open graded aggregate base should then be levelled, with new material added as necessary, followed by the placement of new bedding chip and pavers.

Examples of horizontal creep are illustrated in Figure 10.

horizontal creep

Additional Distresses. Additional distresses that can occur to a PICP include missing pavers, heaving, and patching. Missing pavers occur when sections of pavement completely disappear, either by removal or by disintegration or damage. Any missing pavers can compromise the integrity of the pavement structure and increase roughness, creating a “pothole” effect. Low severity would be considered as a single missing paver. Medium and high severity are indicated by two or more missing pavers, with high severity affecting the ride quality. All missing pavers should be replaced.

Pavement heaves are areas of the pavement surface that have elevations that are raised or higher than the surrounding areas. Heaves are typically caused by differential frost heave of the underlying soils. Heaves can also occur as a result of subgrade instability or in conjunction with settlement or rutting. Low severity is considered when the heave height is between 0.5 and 1.5 centimeters, medium severity between 1.5 and 3.0 centimeters, and high severity greater than 3.0 centimeters. Before mitigating pavement heave distress, it is prudent to undertake a geotechnical investigation to confirm the potential cause(s) of the distress.

A patching distress in a PCIP refers to sections of pavement that are missing pavers and have been reinstated with a dissimilar material (e.g., asphalt patch). For permeable pavers, patching is not recommended, because the patch quality can compromise the integrity of the pavement structure, significantly reduce infiltration, and increase roughness.

Some examples of additional distresses are illustrated in Figure 11.

medium-severity pavement heave, high-severity pavement

patching

Monitoring Program

The monitoring program should be completed on an annual basis; however, with increased sediment and debris, the program schedule may be modified as necessary. It is important that the surface infiltration, secondary drainage features, and structural adequacy are checked to ensure that the system functions properly.

Surface Infiltration Monitoring.

There are two ways of monitoring to determine surface infiltration:

- Observe drainage and look for any standing water immediately following a heavy rain event.

- Conduct surface infiltration tests using ASTM C1781-13.

- Monitoring of the surface infiltration should be completed twice in the first year after construction, followed by annual inspections.

Secondary Drainage Features. The free flow of the secondary drainage features such as subdrains, outflows, and storm drains should be monitored annually and after major rain events. They should be free flowing and free of debris and sediment to allow for outflow of the stored water.

Structural Adequacy. To maintain the structural integrity of the permeable pavement, the pavement should be monitored annually for signs of structural distresses such as settlements, damaged paver units, and edge restraint damage.

Inspection and Monitoring Program

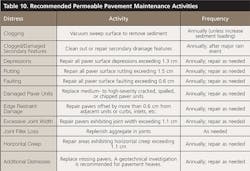

For pavement preservation and stormwater management, it is recommended that annual inspections and monitoring of the PICP be completed. Annual inspections should be completed to ensure that the permeable paver system is providing proper structural support and surface water removal. The structural adequacy inspections for PICPs are similar to those for regular interlocking concrete block pavement. ICPI and ASTM provide guidance for conducting inspections for conventional interlocking concrete pavements. The recommended maintenance activities and frequencies are summarized in Table 10.

Permeable Pavement Maintenance and Rehabilitation

One of the key advantages to PICPs is their ease of maintenance and repairs. Pavers can be easily removed and reinstated, utility cuts can be completed without affecting the pavement life (no patches), and surface cleaning can be completed with standard vacuuming equipment.

Surface and Joint Cleaning. If standing water is ponding on the surface and/or infiltration rates are reduced, the pavement surface should be vacuum-swept to remove the sediment. Sweeping alone is not recommended, and vacuum-sweeping equipment should be used to ensure the sediment is removed. When using air vacuum sweepers, adjustments must be made to the vacuum force to minimize removal of the joint filler stone from the joints.

The depth of vacuuming should be between 1.3 and 2.5 centimeters. Joints should be refilled with clean aggregate (ASTM No. 8, 89, or 9 stone). Once joint filler has been reinstated, the surface should be monitored again to ensure infiltration has been improved to at least 50% of the design infiltration rate or a minimum of 2.5 centimeters per hour. Annual sweeping should be scheduled to take place soon after any significant biomass loading.

Paver Repair. All cracked paver units should be removed and replaced with new pavers. During design and construction of PICP, additional pavers should be ordered and stored for future maintenance and repairs. It is recommended that at least 25 square meters of the same pavers used in the roadway be ordered and kept for future potential use. This is especially critical if aesthetically unique pavers are chosen and installed. Purpose-built removal equipment can be used to remove pavers to prevent damage to surrounding pavers. An example of paver removal equipment is shown in Figure 12.

Surface Deformation Repairs. The majority of the distresses associated with structural adequacy will require the removal and rehabilitation of one or more material layers. The following steps are recommended for repair work completed beneath permeable pavements.

- Remove pavers, clean, and stack for reinstatement. Secure undisturbed pavers with a wood or metal frame.

- Remove and dispose of bedding material.

- Remove base material (can be stored in a clean area for reinstatement). No contaminated aggregate should be reused.

- Re-compact subgrade material as required.

- Reinstate and compact base material (ASTM No. 57).

- Place and screed new bedding material (ASTM No. 2).

- Reinstate pavers, fill joints (ASTM No. 8, 89, or 9 stone), and compacted surface. Place pavers at least 2.5 centimeters above undisturbed pavers prior to compaction.

Edge Restraint Damage. Loss of lateral restraint from edge strips, curbing, etc. can contribute to a variety of distresses including loss of joint filler and bedding material, excessive joint width, and paver rotation. Repairs to rehabilitate loss of edge restraint damage must address both the cause of loss of lateral support and the resulting pavement distresses such as widened joints, material loss, and paver rotation.

Utility Cuts. The ICPI has published a PICP guide that provides information on design, specifications, construction, and maintenance for permeable concrete pavements. To repair underground utilities, the following steps be completed:

- Remove pavers, clean, and store for reinstatement. Secure undisturbed pavers with a wood or metal frame.

- Remove and dispose of all bedding material.

- Remove stone reservoir base material (and store in a clean area for reinstatement). No contaminated aggregate should be reused.

- Excavate or re-compact subgrade material as required.

- Repair or install utility as required.

- Use flowable concrete fill to support repaired utility to provide support for the stone reservoir base. If flowable fill is not used, it is recommended that a dense graded base be placed and compacted in lifts not exceeding 15 centimeters to 100% of the standard Proctor maximum dry density. The dense graded aggregate should extend to the top of the adjacent open graded subbase aggregate.

- Reinstate and compact stone reservoir base material.

- Place and screed new bedding chip material.

- Reinstate pavers, fill joints, and compacted surface. Place pavers 1.2 centimeters above undisturbed pavers prior to compaction. After compaction, the pavers should be no more than 0.2 centimeter above the elevation of the surrounding pavers.

- Sweep surface to remove any excess debris.

Permeable Pavement Preservation Recommendations

To maximize the effective life of the permeable pavement, the following activities are recommended:

- Do not use conventional oil- or latex-based pavement marking materials. Colored paving blocks can be used to indicate centerline, parking stalls, designated parking areas, etc.

- Limit standing of vehicles that might leak engine oils and lubricants on the pavement.

- Limit activities that might increase the potential of joint clogging.

- Limit, where possible, frequent heavy vehicle use of the pavement; for example, do not increase bus traffic, do not designate as a truck route, and limit the roadway use for construction detours.

- Avoid the use of deicing chemicals and winter sand.

- Take caution during street cleaning where power-washing equipment is used. Prevent the removal of joint filler material.

References

AASHTO. 2001. Pavement Management Guide, AASHTO Joint Task Force on Pavements. ISBN-1-56051-155-9. American Association of State Highway and Transportation Officials. Washington DC.

ASTM E2840-11. Standard Practice for Pavement Condition Index Surveys for Interlocking Concrete Roads and Parking Lots. American Society of Testing and Materials International. West Conshohocken, PA.

Ferguson, B. K. 2005. Porous Pavements: Integrative Studies in Water Management and Land Development. CRC Press. Boca Raton, FL.

ICPI. 2011. Smith, D. R. Permeable Interlocking Concrete Pavements, Design, Specification, Construction and Maintenance. Interlocking Concrete Pavement Institute, Herndon, VA.

NCDENR 2012. Stormwater Best Practice Manual. North Carolina Department of Environment and Natural Resources. Raleigh, NC.

USEPA. 2010. Surface Infiltration Rates of Permeable Surfaces: 6 Month Update. Washington DC.David Hein has presented several webinars through Forester University on permeable pavements and roadway construction, including the Permeable Pavement Master Class Series. To view these presentations as on-demand webcasts, visit www.ForesterUniversity.net.