Report assesses life cycles of stormwater pipe materials

IRVING, Texas – Corrugated high-density polyethylene (HDPE) pipe carries the least environmental burden compared to other commonly used pipe for stormwater drainage and culvert applications. This was the conclusion of a recently completed life-cycle assessment study that was conducted by an independent firm, Franklin & Associates. The report was made available by the Plastics Pipe Institute, Inc. (PPI). Life Cycle Assessment of North American Stormwater Pipe Systems – TR-53, is available for free at the association’s Drainage Division’s website: https://plasticpipe.org/pdf/tr-53-2021.pdf. PPI is the major North American trade association representing the plastics pipe industry.

“This life cycle assessment investigated reinforced concrete, corrugated steel, PVC, and two types of corrugated HDPE pipe,” stated Daniel Currence, P.E., director of engineering for PPI’s Drainage Division. “HDPE pipe made with virgin resin and HDPE pipe made with recycled content were found to have the best overall sustainability rating.

“The analysis evaluated several different pipe systems in all life-cycle phases, including raw material extraction, pipe material production, fabrication, installation, repair, and end of life. The study was conducted following internationally accepted ISO standards for Life Cycle Assessment (LCA) methodology. When faced with input decisions that might sway the assessment, we chose to use values that actually benefited competing materials. We also used competing materials’ own, publicly reported environmental data. The study still recognized that corrugated HDPE pipe as the most environmentally friendly storm sewer material available.”

According to Emily Lorenz, P.E who conferred with PPI on the project, “In general, the study showed that HDPE pipe performed better by a significant margin than the other pipe material systems. It is important to know that the study was performed in accordance with ISO 14040 and ISO 14044 for comparative assertions, as mandated by the standards. Plus, because the plastic pipe was being compared to other systems, the report had to go through an additional level of technical scrutiny in order to validate the results. After Franklin Associates completed the study and the report, the report had to go to through an independent and external peer review to make sure that the choices that were made did not benefit those who were involved with the study.” Lorenz is an independent consultant in the areas of LCA, EPDs, PCRs, green building, and sustainability and has worked on ISO standards, various industry codes and serves as chair of ASTM E60 Committee on Sustainability and participates in the ASCE/SEI Sustainability Committee.

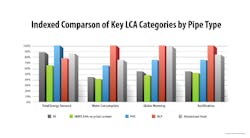

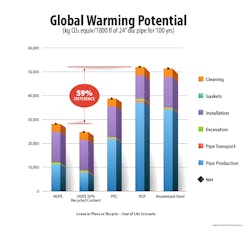

The LCA evaluated the various pipe materials across a variety of environmental impact categories, including energy demand, solid waste, water consumption, global warming, acidification, eutrophication, ozone depletion, and smog formation. “In all categories, corrugated HDPE pipe made with recycled resins had the lowest environmental impact,” Currence stated. “HDPE pipe made with only virgin resins followed closely behind. In the key impact category of global warming potential, corrugated HDPE pipe had approximately 50 percent of the potential impact of concrete and corrugated steel pipe.

Sustainability Challenge

The LCA study was undertaken by PPI to identify and address the vast and varied pieces of information about the environmental impact of pipe. “There are a lot of claims about sustainability among competing materials,” Currence explained. “And they are all scattered, so we felt it would be a good idea to capture them all in one place for analysis. Using the ISO methodology enabled the LCA to provide a realistic comparison. The LCA compared 1000 linear feet of 24-inch diameter storm sewer pipe. And we were generous in our assumptions. This included using environmental data for other materials from their own sources, and not generated by PPI funds, we assumed all materials had a 100-yr service life, even corrugated aluminized pipe (something PPI routinely disputes), and we cut the amount of imported backfill material needed for RCP installation in half. We took these steps as an attempt to eliminate as much controversy as possible.”

“Being an industry resource for 70 years, PPI continually conducts research studies into plastic pipe. This Life Cycle Assessment of North American Stormwater Pipe Systems report is a valuable tool that is our most recent effort in this area. It provides specifiers, owners, municipalities and others with useful information when selecting which technology to employ for stormwater pipe systems. Dan Currence and the members of the PPI Drainage Division spent literally three years on this project. Their exacting work is to be congratulated.”

Summing up the report, Lorenz commented, “The HDPE pipe LCA looks really, really good, and when you talk about the HDPE pipe having 40 percent recycle content, it looks fabulous.

“In my mind, all things being equal, you can get a reduced environmental impact by choosing the plastic pipe,” she stated. “With the performance characteristics obtained with the HDPE pipe and the reduction in environmental impact, that’s a win-win.”

More information can be found at www.plasticpipe.org and the PPI Drainage Division https://plasticpipe.org/drainage/.

About PPI

The Plastics Pipe Institute, Inc. (PPI) is the major North American trade association representing the plastic pipe industry and is dedicated to promoting plastic as the materials of choice for pipe and conduit applications. PPI is the premier technical, engineering and industry knowledge resource publishing data for use in the development and design of plastic pipe and conduit systems. Additionally, PPI collaborates with industry organizations that set standards for manufacturing practices and installation methods.