Southwest Florida has some of the worst surface water quality in the United States used for irrigation. The demand for water due to community coastal development and farming has placed a strain on the aquifers drawn from wells.

Saltwater intrusion has become problematic, and many existing wells had to be abandoned due to the high concentration of salt. To mitigate the contamination of saltwater intrusion, water management districts in Florida have been promoting conservation through cost sharing grants to convert farmers from well water to surface water sources.

Municipalities have changed the design of wastewater treatment plants to incorporate retention ponds to store treated water for reuse that is pumped into water distribution irrigation systems that feed golf courses, gated communities, and farms.

Well water vs. surface water

The equipment used for well water and surface water is very different. Well water requires long shaft turbine pumps and simple static type filters/strainers (Fig. 1) to remove inorganic suspended solids from underground water sources; compared to surface water requiring centrifugal pumps and more complex self-cleaning automatic filters to remove both organic and inorganic particles.

The importance of the correct selection of the filtration is based on two factors: the irrigation emitting device orifice size and the clogging factors of the suspended solids. Underground water sources tend to be predictable for suspended solids concentration and require simple static filters that are manually cleaned on a time schedule.

Surface water sources are more challenging and are subject to many environmental influences.

Wind, storm events, fertilizer laden run-off, and solar radiation can change solids concentration over-night, which affects the work-load characteristics of the filtration equipment. A simple static filter would not be a good choice for a surface water application because of the variability of the water quality and concentration of suspended solids.

As the name suggests, self-cleaning automatic filters are autonomous, they monitor the status of the media that stops and collects the suspended solids. However, there are other biological & dissolved constituents that must be chemically treated, and that method can vary greatly based on water quality testing. Chlorine (sodium hypochlorite) injection followed by flushing is the standard for controlling biologicals; precipitation of iron and calcium are handled with acid-based solutions followed by a flushing process. The concentration and amount rate are dependent on water quality analyses and system flow rates. The focus here is on suspended solids and their removal through mechanical filtration means.

Filter types

The most popular filter types for surface water applications are self-cleaning weave-wire screens (Fig. 2), discs (Fig. 3), and sand-media (Fig. 4). Each type has been successfully used both in agriculture and water reuse applications. The selection of one type over another is based on the end-user capabilities for maintenance, application type, footprint size, and initial costs.

Sand media filtration

Sand media filtration has been around for a long time. The main resistance to using this technology is due to footprint size, maintenance of the media, and the amount of water & energy used during a cleaning cycle.

Disc filtration

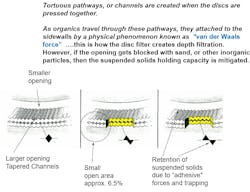

Disc filtration has a reputation as the costliest of the three technologies, highly complex, footprint size and configuration limitations, and requires a highly skilled maintenance person or contractor to work on them. Acid washing the discs once or twice a year is a requirement to clean the grooves in the discs that capture suspended solids. The self-cleaning screen technology has the least moving parts, small footprint size, many configuration options, and is the easiest to maintain and comprehend for personnel.

The Florida market not only has to contend with suspended solids consisting of algae, sand, and detritus, but also living organisms such as adult snails (Fig. 5) and larvae.

Snails enter the irrigation distribution systems from natural and water reuse ponds as larvae or adults. Once introduced, they are difficult to eradicate because they begin to live and breed within those systems and can easily overwhelm point-of-use manual filters. These clogging issues with manual filters lead to higher maintenance.

Sometimes end-users will remove the manual filters, which only exacerbates problems with additional clogging and damage to the water emitting devices.

In practice

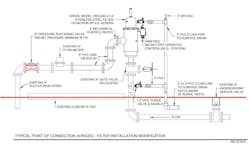

A prominent gated community had such a problem and contacted Orival Filters for four main above ground installation sites fed from a water purveyor’s mainline system (Fig. 6).

The four sites were identical which made the design and future maintenance access reasonable for the owner.

Field measurements were taken, and a design layout (Fig. 7) produced for the board of directors for approval. The filtration degree requirement is typically 200-micron, however, to be efficient at removal of the snails 120-micron was chosen based on research and the recommendation by the University of Michigan.

After approval, the board of directors solicited three bids from installation contractors and the project was awarded to the most qualified company. The installation took approximately one week for the four locations with minimal interruption of the irrigation supply water.

Since the installation of the 120-micron filtration systems (Fig. 8), the maintenance manager has seen an 80-90% reduction in maintenance in the original basket-type cartridge filters.

Summary

An effort was made to find the best solution for this application. The self-cleaning screen filter had several advantages over the other technologies.

First, this method had already been tested and used in similar applications; secondly, it was aesthetically more appealing to the owner. The most important deciding factor was that the weave-wire media is a static barrier against compromising the water system with adult snails and larvae.

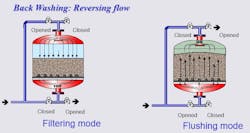

The disc system has dynamic media, meaning the discs open and close during the cleaning cycle. There would be a high potential for an adult snail to become wedged between the discs opening a pathway to further contamination.

The sand media was not considered at all due to the overall foot-print size and the amount of work that would be required to connect to the existing piping system.