In Fiscal Year (FY) 2013, the SWANA Applied Research Foundation’s (ARF) Waste-to-Energy (WTE) Group identified the topic of researching opportunities to enhance the benefits and reduce the costs of WTE facilities as being of primary interest to the group.

This research topic was submitted by Paul Hauck of CDM Smith, who provided the following description:

“[The SWANA Applied Research Foundation should] investigate innovative options and ancillary processes used by existing WTE facilities to maximize their performance as parts of integrated solid waste management systems. Examples of internal use of electricity, processing WWTP biosolids, used tires, C&D combustibles, biomass combustion, etc., should be cited.”

The goal of this research effort was to develop and publish a series of case studies of successful, client-generated innovations that have resulted in reduced costs and/or increased revenues and other benefits at WTE facilities in North America.

In addition to recovering energy from municipal solid waste (MSW), generating a biologically and chemically stable ash residue, and reducing the waste disposal volume by more than 70%, WTE facilities provide a number of additional benefits which are often overlooked. This article will highlight some of these benefits. Additional information on these benefits, as well as innovations that have been implemented to reduce WTE costs, are documented in a SWANA ARF report that will be published in December 2013.

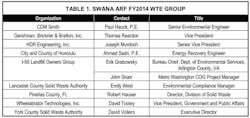

This article is based on research that has been supported and conducted with input and guidance provided by the ARF’s WTE Group Subscribers who are listed in Table 1.

(The SWANA Applied Research Foundation was founded in 2001 with the purpose of conducting collectively defined and funded applied research on pressing solid waste issues. It is funded by local governments and other organizations that contribute a “penny per ton” of waste managed to the Foundation on an annual basis. For more information on the SWANA Applied Research Foundation, please contact Jeremy O’Brien, Director of Applied Research, SWANA, 301-585-2898.)

WTE Benefits You May Not Have Considered

WTE facilities can be used to combust a number of special waste streams commonly generated by a community, including:

- Wastewater treatment plant biosolids

- Nonrecyclable scrap tires

- Off-spec/out-of-date manufactured products

- Confidential documents

- Discarded pharmaceuticals

- Bulky wastes

By processing these wastestreams, WTE facilities can both provide important waste management services to their communities as well as raise additional revenues to offset the tipping fees charged for MSW processing.

Wastewater Treatment Plant Biosolids

Biosolids are the nutrient-rich organic materials resulting from the treatment of wastewater, i.e., the solid, semisolid or liquid untreated residue generated during the treatment of sewage in a wastewater treatment facility (http://goo.gl/an6fOh). Biosolids and products derived from biosolids are a potential source of pharmaceuticals and other emerging contaminants to the environment.

Wastewater treatment plants (WWTPs) in the United States generate approximately 7 million dry tons of biosolids each year. Because these biosolids are rich in plant nutrients, they are frequently applied to soils to fertilize plants and to improve the quality of soil. Due to a variety of pharmaceuticals and other organic chemicals have been found in the wastewater discharged from WWTPs, questions have been raised about the presence of these chemicals in biosolids. The application of municipal biosolids on land may be a widespread source of these emerging contaminants to surface and ground water (http://goo.gl/Fjv47z).

Thermal processing at WTE facilities can significantly reduce the volume of biosolids disposed in landfills, recover energy from the biosolids, and produce a sterile, harmless residue that is free from volatile content. Co-firing biosolids in a WTE facility provides a safe alternative solution when facing problems dealing with land scarcity available for waste disposal while recovering energy generated in the combustion process, especially in urban areas which have large treatment plants and, consequently, large biosolids volumes (http://goo.gl/rRmsdN).

The ARF research identified WTE facilities in Huntsville, AL, Hillsborough County, FL and Lee County, FL which have tested or are currently co-firing biosolids with MSW in their operations. Honolulu is at 70% design for a separate sludge receiving and handling system that would use the following: 1) receiving bin; 2) Schwing pumps; and 3) a series of injection nozzles that would spread sludge onto the grate system.

Nonrecyclable Scrap Tires

In 2003, the US generated approximately 290 million scrap tires. Historically, these scrap tires were landfilled, stockpiled, or illegally dumped, which created breeding grounds for mosquitoes and rodents. Fortunately, markets now exist for over 80% of these scrap tires-up from 17% in 1990. These markets-both recycling and beneficial use-continue to grow. The remaining scrap tires, however, are still stockpiled or landfilled.

The three largest scrap tire markets are tire-derived fuel, civil engineering applications, and ground rubber applications/rubberized asphalt.

Scrap-tire-derived fuel, or TDF, is an attractive option because of the high heating value of tires. Compared to other commonly used solid fuels, the heating value is 25%-50% higher than coal and 250%-300% higher than MSW. State and federal studies have repeatedly shown that using tires to generate energy is environmentally sound when used in appropriate applications that ensure complete combustion, have proper air pollution controls in place, and conduct all required testing, monitoring, and other regulatory requirements.

Whole tires are banned from landfill disposal in many states. For communities located in these states, the combustion of scrap tires in WTE facilities offers an economical and sustainable method of processing that utilizes the energy recovered from tire combustion to generate electricity. In this regard, tires will typically require removal of rims and some pre-processing, such as shredding or cutting into halves or quarters.

WTE facilities which combust used tires include the following:

- Lee County [FL] WTE Facility– Tires from commercial sources received at the WTE facility for processing at a tipping fee of $105 per ton. Approximately 300-350 tons are received per month. After shredding, tires are utilized as fuel at the WTE facility (Lee County Solid Waste Division. Providing Responsible Solid Waste Management Through the Use of an Integrated Solid Waste Management System and Resource Recovery Principles.).

- Pasco County [FL] WTE Facility– The Pasco County WTE facility charges $100 per ton the disposal of tire compared to the tipping fee of $56.70 per ton for MSW. The tires are cut in half and mixed with the MSW for combustion in the WTE facility.

- Honolulu WTE Facility– The city of Honolulu performed a test burn of whole (uncut, unshredded) passenger tires with and without rims in July 2013. Initial results are under review and so far look favorable. The city hopes to start regular deliveries in the near future.

Off-Spec/Out-of-Date Manufactured Products

Manufacturers often need product destruction services for off-spec or out-of-date products. One of the most effective methods of product destruction is combustion. As documented below, WTE facilities can provide this service to industries in the communities that they service. This option offers the triple benefits of providing a needed service for local industry, securing an additional revenue stream for the WTE facility and recovering the energy released during the combustion process for electricity generation.

Many of the WTE facilities in North America are processing off-spec/outdated products for energy recovery. The Lancaster County, PA, facility is exemplary in this regard.

The Lancaster County Waste to Energy (WTE) Facility is a 1,200-ton-per-day mass burn waste-to-energy plant that has been in operation since 1991. The plant is owned by the Lancaster County Solid Waste Management Authority (LCSWMA), but is operated for LCSWMA by Covanta Lancaster. During the initial years of operation, only municipal solid wastes (MSW) were combusted. The picture has changed dramatically, however, since those early days.

The WTE facility has successfully processed hundreds of different industrial waste streams since 1994 (Forster, G. Dealing with Residual Wastes at the Lancaster County Resource Recovery Facility. Paper presented at the 10th North American Waste to Energy Conference. (NAWTEC 10-1019). ASME 2002.). The list of industrial waste categories processed at the WTE facility includes:

- Pharmaceuticals (US Drug Enforcement Administration-controlled substances from local law enforcement agencies, pharmaceutical manufacturers and DEA licensed reverse distributors; non-controlled pharmaceuticals)

- Health care products

- Oily debris

- Surface coatings

- Industrial wash waters

- Confidential documents

- Food products

The Lancaster County WTE facility has demonstrated that a wide assortment, as well as significant quantities, of industrial wastes can be successfully processed at a WTE facility. For example, in 2012, the WTE facility combusted approximately 25,000 tons of industrial waste, which represented 6.5% of the 387,000 tons of waste processed that year. Accepting industrial waste not only benefits LCSWMA, but the waste generators are satisfied that the facility will provide for the complete destruction of their products, thereby reducing their liability concerns associated with the unintended use of these products. Furthermore, these waste materials are used for energy production at the WTE, instead of going directly to the landfill.

Discarded Pharmaceuticals

Pharmaceuticals that are unwanted (e.g., expired or unused) by consumers (households) are not regulated as hazardous wastes and are generally considered municipal solid wastes. In this regard, it is noteworthy that the U.S. EPA currently recommends thermal processing as the preferred disposal method for household drug take-back programs because it believes that thermal processing will address both environmental and diversion concerns (Rudzinski, S. USEPA. Memo: Recommendation on the Disposal of Household Pharmaceuticals Collected by Take-Back Events, Mail-Back, and Other Collection Programs. Sept. 26, 2012.).

This recommendation bodes well for communities with access to WTE facilities. In contrast to implementing costly and relatively ineffective pharmaceutical take-back programs, these communities can simply encourage their residents and businesses to dispose of these items in their solid waste containers rather than flushing them down the toilet. The subsequent combustion of these products in WTE facilities will assure that they are properly managed as well as enable the recovery of their energy values.

MRF Residues

Material recovery facilities (MRFs) are facilities that are designed to process the recyclables generated in community recycling programs to meet the specifications and other needs of the secondary material marketplace. In 2008, there were 1,343 MRFs operating in the US (Berenyi, E. Materials Recycling and Processing in the United States: 2007-2008.) In spite of the goal of maximizing materials recovery, all MRFs generate a residue stream consisting of nonrecyclable materials and residues that cannot be marketed.

One option available to communities is to recover the energy value inherent in MRF residue streams by processing them in WTE facilities. This option has been implemented at the Lee County [FL] WTE Facility.

The Lee County MRF manages all residential recyclables collected from Lee County residents. The 550-tpd single stream facility processes single stream recyclables and recovers newspaper, mixed paper, office paper, junk mail, catalogs, cardboard, plastics (No. 1-No. 7), ferrous metal, aluminum and mixed glass. As a result, the county was ranked as the top recycling county in Florida in 2008, with a recycling rate of 43% (HDR Engineering. Lee County Integrated Solid Waste Management System. 2011 SWANA Integrated Solid Waste Management Excellence Award Nomination). Nonrecyclable items identified and separated at the county’s material recovery facility are transported to the WTE facility and converted into renewable energy by combustion.

Bulky Wastes

Bulky waste is a term used to refer to waste items that are too large to be accepted by the regular waste collection. Bulky waste items include discarded furniture, large appliances and plumbing fixtures. Branches, brush, logs and other green waste are also categorized as bulky waste, although they may be collected separately for shredding and/or composting.

Bulky wastes are processed for energy recovery at the McKay Bay WTE facility in Tampa, FL. At the city of Tampa’s transfer stations, a front-end loader is used to break apart combustible bulky waste items such as furniture and box springs. The combustible portion of the bulky waste is then transferred to the adjacent McKay Bay WTE facility for combustion and energy recovery.

Alternatively, the city of Honolulu uses a SSI Pri-Max 770 bulky waste shredder to process its bulky waste before combustion.

Many other WTE facilities in North America have implemented similar strategies for energy recovery from bulky wastes.

Conclusions

This brief review highlights some of the additional benefits that WTE facilities provide to their communities. WTE facilities can provide synergistic benefits to other components of an integrated solid waste management system, such as the processing of MRF residues. They can solve an often intractable problem created by a community’s wastewater treatment system-namely, the disposal of wastewater biosolids. They can provide important waste processing services to manufacturers that need assured destruction of off-spec or out-of date products and businesses requiring destruction of confidential documents. Finally, they can provide for the thermal processing for discarded pharmaceuticals as recommended by the EPA.