Staying within the lines: Replacing aging infrastructure under tight restrictions

Key Highlights

- Fayette County manages nearly 120,000 residents with aging stormwater infrastructure requiring costly upgrades and replacements.

- The project faced challenges such as hidden deterioration, ROW restrictions, and the need for innovative solutions like MARMAC couplings to connect old and new pipes.

- Flexibility, resourcefulness, and specialized products are key to successfully upgrading stormwater systems within legal and budget constraints.

A County at the Crossroads

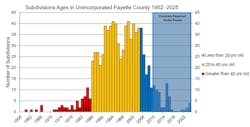

Southwest of Atlanta, within the fast-growing Metro Atlanta region, sits a county of nearly 120,000 residents across five municipalities and another 55,000 in unincorporated communities. Spanning almost 199 square miles—150 of them unincorporated — the county faces a pressing challenge: maintaining and replacing aging stormwater infrastructure while staying within the boundaries of public right-of-way (ROW) and existing easements. The zinc-coated galvanized materials predominantly used in the Southeast, particularly in subdivisions within Fayette County constructed between 1986 and 2006, are approaching, or have reached, the end of their estimated service life, which ranges from 20 to 40 years1.

Since the Fayette County Board of Commissioners approved its current extent of service for stormwater infrastructure in 2008, the Environmental Management Department has been tasked with maintaining the county’s Municipal Separate Storm Sewer System (MS4). Expansion of the MS4 is allowed only under strict conditions. A system must:

- Connect directly to the existing network

- Present a genuine threat to health, property, or the environment

- Receive significant flow from the county’s infrastructure

- Not result of private negligence

- Have proper easements in place

These requirements create a delicate balancing act: protecting infrastructure while staying firmly within the lines of what the county can legally and financially manage.

Case Study: Fox Hall Farms

Fox Hall Farms, a subdivision developed between 1992 and 1996, offers a snapshot of the stormwater replacement challenge in older neighborhoods. Built in four phases, the development contains eight stormwater systems and 13 catch basins —all now approaching three decades of service.

In 2024, Fayette County undertook its first full replacement of the neighborhood’s stormwater infrastructure. The scope of work included:

- 288 linear feet of pipe – ~$101,700

- 12 catch basin tops – ~$58,000

- 3 MARMAC connections – ~$1,700

- 3 manholes/junction boxes – ~$36,000

- Total construction cost (8 systems) – ~$305,000

The project was funded through a combination of SPLOST (Special Purpose Local Option Sales Tax) and general funds.

The challenge of staying inside the ROW

On paper, the Fox Hall Farms project appeared straightforward: trenching and replacing old pipes. In practice, the work proved far more complex.

Aging infrastructure often conceals its true condition until excavation begins. Crews quickly discovered problems extending beyond ROW boundaries and onto private property—areas inaccessible without new easements or budget reallocations. As a result, engineers were forced to tie new piping into deteriorated systems at the ROW boundary, demanding creativity and flexibility.

Sinkholes, collapsing catch basins, and even roadway failures are frequent reminders that stormwater systems built 25 to 30 years ago often fall short of modern standards. Each dig carried the risk of uncovering additional hidden failures.

Innovation in the trenches: MARMAC couplings

To bridge the gap between new reinforced concrete pipe (RCP) and older corrugated metal pipe (CMP), the county raised the question during a training session conducted by the Georgia Concrete Pipe Association. During the discussion, one instructor mentioned MARMAC couplings, manufactured by MarMac Construction Products, as a potential option. These couplings use a reinforced mastic and mechanical band system designed to seal and restrain external pipe joints.

While not originally intended for joining deteriorated CMP to new RCP, the couplings provided a practical solution when ROW and budget constraints ruled out building new junction boxes.

Challenges included:

- Deteriorated CMP is too weak to withstand strap pressure

- The need for a concrete saddle over the coupling to prevent collapse

Despite these obstacles, the couplings offered a workable link between new and old systems, ensuring continuity. Importantly, the difficulties encountered were due to site conditions — not product performance.

Lessons Learned

The Fox Hall Farms project highlights the complexities of stormwater replacement under ROW restrictions. Success required:

- Flexibility to adapt plans as conditions changed

- Innovation in using specialized products like MARMAC couplings

- Resourcefulness in balancing costs, easements, and construction methods

As one project manager reflected, “The true test of success will be time.”

For counties working under similar restrictions, Fox Hall Farms serves as both a cautionary tale and a model of innovation—demonstrating that even within tight boundaries, it is possible to stay within the lines while protecting vital infrastructure.

References

1 - National Corrugated Steel Pipe Association. CSP Durability Guide: Product Usage Guidelines for Corrugated Steel Pipe. Washington, DC: National Corrugated Steel Pipe Association, May 2000. Available from https://www.conteches.com/media/4iwpslij/tech_durabilityguide.pdf