Conservation District Preserves Pond

About the author:

Best Management Products

www.bmpinc.com | 800.504.8008

Space is a premium for most storm water designers, so getting the highest pollutant removal with the least amount of constructed area is desirable. Within the Municipality of North Perth, ON, Canada, a conservation district steward wished to reduce the pollutant load washing into a pond within a park the district encompasses.

The concern was that sediment and gross solids had the potential to over-burden the small pond and reduce the effectiveness of its ability to serve as a sink for fine solids and be a recreational asset in the park. Here, pre-treatment was the primary function. A small structure with a Turbo Plate array and a Snout would meet the needs to preserve the pond and remove larger particles out of the water before it entered the pond. For this application, a 1,200-mm ID man- hole with a 1,200-mm sump; a 300-mm inlet and outlet pipe with a TP18 array; and an18R Snout covering the outlet pipe were chosen.

Whether serving as a primary or pre-treatment purpose, reducing the structural footprint of a water quality improvement vault by using Turbo Plates to reduce flow energy can result in saved space and lower costs.

For the past two years, Best Management Products Inc. (BMP) has been developing a method to reduce turbulence and velocity inside a storm water structure with a sump. Designers have been asking for ways to increasing sediment capture in these structures to boost the utility of existing infrastructure. Offline sump catch basins with Snouts—mean- ing there is only an outlet pipe—already have shown total suspended solids (TSS) reductions in excess of 70%.

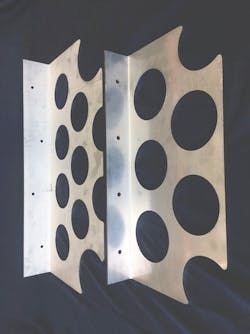

A solid deflector plate directs flow from an incoming pipe to perforated plates, thus both the flow path is lengthened, and the surface area that the flow moves past is increased. The resulting drop in velocity and turbulence yield a significant increase in sediment capture and retention.