Contech Releases Optimizer Storm Water Solution

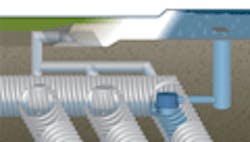

Contech Construction Products Inc. has developed the Optimizer, an innovative new underground detention technology system and solution engineered to stabilize and manage stormwater runoff. This technology is the smallest and most efficient storm water runoff method or system in the marketplace.

Optimizer detention systems contain innovative flow control devices that use pressure head to begin immediately discharging at the maximum allowable rate, reducing required storage volume. The result is a smaller, more economical corrugated metal pipe detention system.

The process lowers project installation costs due to less excavation and backfill necessary on the smaller-sized solution, which speeds up installation. Less pipe is also installed in this smaller footprint solution, which is ideal for tight sights where larger, traditional systems will not work.

Current systems collect and temporarily store excess runoff, while discharging the water at rates not exceeding predevelopment levels. The new Optimizer technology is based on a series of flow control tank processes to allow the system to instantaneously discharge at the maximum allowable rate. A pressure build-up process inside system surge tanks allows for the quick discharging to occur.

A designer is now able to discharge to maximum allowable rates sooner with the Optimizer than with any other system. And, due to the small size of this new technology compared to conventional systems, it saves significant costs by actually decreasing the quantity of water that needs to be stored.

As underground detention systems are many times considered the best solutions, the Optimizer is also much safer than open ponds, which unnecessarily utilize land and usually incur high maintenance costs.

The process reduces the size of standard detention systems by up to 50% over current technology, which are inefficient during the early stages of design storms.

Source: Contech