With their myriad benefits, green roofs are becoming increasingly incorporated into new and existing projects. The International Green Roofs and Walls Project Database lists 1,599 projects totaling 33,334,677 square feet, and the number is growing.

Green roofs—also known as vegetated or garden roofs—are key green infrastructure elements and are being increasingly recognized for their “valuable ability to absorb, reduce, and delay stormwater from reaching sewers or other grey infrastructure systems,” says Richard Hayden, garden roof product manager with Chicago-based American Hydrotech.

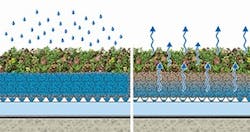

Green roofs work by storing rainwater in several areas of a layered assembly: in open pore spaces of the growing media and within the drainage and water retention system that underlies the growing media and plantings.

The rainwater is retained until the assembly is completely saturated, and excess water is slowly released from the roof into the site’s stormwater system. Stormwater runoff volume also is reduced because of evapotranspiration, which cools the surrounding air.

Green roofs filter particulate matter and chemicals through the plants, growing media, system filter, and drainage layers, mimicking natural hydrology systems such as wetlands and similar structures.

In summer, most green roofs stay cooler than conventional rooftops and help buildings stay cooler with less heat flowing through the roof. Lower green roof temperatures result in less heat transfer to the air above the roof, keeping urban air temperatures lower as well.

Green roofs are an option for stormwater management that not only reduces the volume of stormwater, but improves the water quality coming off of rooftops, notes Dr. Marty Wanielista, director of the Stormwater Management Academy at the University of Central Florida (UCF).

“As another major benefit, green roofs put more oxygen into the atmosphere and reduce temperature around the building site,” he says. (See also the Reader Profile on page 58.)

The Stormwater Management Academy serves as a research source for education and training programs in nationwide partnership with governments, non-governmental organizations, and industry. Green roof technology is one of the research areas at the Stormwater Management Academy, which also studies low impact development (LID) technologies, water-quality management and pollution control technologies to reduce receiving water impacts, erosion and sediment control with smart sensors and materials and system analysis, climate change impacts and urbanization efforts on flood and drought, and stormwater treatment and reuse.

What started off as an effort to add green space on buildings for purely aesthetic purposes has morphed in a very important BMP option for handling rainwater at the point where it lands on the roof, Hayden points out.

American Hydrotech manufactures and supplies waterproofing and roofing components for projects worldwide. Its flagship product is the original hot, fluid-applied rubberized asphalt, Monolithic Membrane 6125. Originally developed in the 1960s as a waterproofing element for bridge structures in Canada, MM6125 is now used for creating green roofs.

Its seamless application makes it impervious to the effects of the wet conditions that are typical of green roofs, says Hayden. In 1996, Hydrotech introduced the Garden Roof Assembly and has since supplied waterproofing, drainage materials, lightweight growing media, and plants for more than 2,000 projects in the US and Canada.

“There are many municipalities like New York; Chicago; Philadelphia; Washington DC; and Portland, Oregon, where green roofs are being encouraged through incentives of various types,” says Hayden. “These cities are part of a significant and growing group seeking out innovative ways to minimize or slow down stormwater from reaching already overtaxed sewers.”

Water retention, left, versus evapotranspiration, right

Types of Green Roofs

An intensive green roof is used for visual aesthetics as well as stormwater benefits. Building owners often install them to save energy and provide a garden environment for the enjoyment of building occupants or visitors.

Intensive garden roofs incorporate media depths of 6 inches or more. “These deeper assemblies can allow for a broader array of plant materials including groundcovers, shrubs, and small trees,” says Hayden. “With special considerations, full-size shade trees can be planted on roofs.”

An extensive roof is a green roof dedicated primarily to stormwater management. Although it has aesthetic value, its main purpose is to minimize stormwater runoff and the urban heat island effect.

Hayden notes that the reduction in the heat island effect is the result of actions of water storage and plant growth to create a cooling effect in the immediate area.

“As one of the early identified environmental benefits of green roofs, this cooling effect has been known to create more than a 50 degree Fahrenheit differential between vegetated and non-vegetated surfaces,” he says.

Extensive garden roofs are the most common green roof type. With growing media depths between 3 and 6 inches, extensive green roofs can support a wide array of drought-resistant vegetation such as sedums and certain perennial plants.

Extensive roofs typically capture between 50% and nearly 100% of rain depending on the amount of growing medium used, the density of vegetation, the intensity of an individual rainstorm, and the frequency of local rain events, according to an EPA report, “Reducing Urban Heat Islands: Compendium of Strategies.” Roof slopes and types of growing media are other influencing factors.

American Hydrotech’s Lawn Garden Roofs are assemblies designed specifically for supporting turf grasses for lawn areas, with media depths ranging from 8 to 12 inches, says Hayden.

“The features in Garden Roofs that are designed to support thriving plant materials also make them ideal for stormwater management,” he says. “LiteTop is Hydrotech-engineered growing media. It has large amounts of pore spaces that create tremendous water storage capacities within the media.

“Where standard top soils may have 5 to 10% open pore space, LiteTop-engineered growing media often have 40 to 50% or more open pore space,” he adds. “In addition, synthetic drainage/retention panels are incorporated into the assemblies. These panels store excess water for plant use when the media dries out. These panels also perform an important aeration function by adding air in the lower portions of the assembly, which reinforces plant viability. When these growing media are combined with synthetic drainage and retention panels, tremendous amounts of stormwater can be stored.”

How Green Roofs Work

Green roofs essentially act as sponges on a roof, says Hayden. “The green roof stores water in the structure of the lightweight media as well as in the drainage and retention panels,” he says. “Succulent vegetation such as sedums also can store water. During a rain event, rather than immediately flowing off the roof through the drains, the water is absorbed in the media and drainage or retention panels.”

During small rain events, water often never leaves the roof. In larger events, the rain continues to fall and saturate the assembly. At that point of saturation, excess water begins to flow off the roof and into the drains.

“This takes time—sometimes hours—to occur,” says Hayden. “This time is often long enough to help downstream storm facilities catch up to the storm. This delay is a very important BMP feature. When properly acknowledged in the design process, green roofs can reduce the need for and size of downstream stormwater facilities.”

Green roofs also can reduce the total amount of water that would otherwise enter the storm sewers. “Normal evaporation of the water via the media plays a part in reducing this water volume,” says Hayden. “Plants transpire a significant amount of this water as well through the normal natural growing processes.”

The ability of green roofs to detain, reduce, and delay stormwater is getting more and more attention as a BMP, says Hayden. “There are a lot of civil and stormwater engineers that are taking notice of these benefits,” he adds.

Green roof on the headquarters building of the World Wide Fund for Nature in Washington DC

Benefits

Green roofs offer a host of benefits, of which stormwater mitigation is one.

In a Portland, OR, green roof demonstration project, a 15-month study of runoff reductions showed that a green roof with about 4 inches of growing medium reduced runoff by almost 70%. The retention rate appeared to increase over time, which was believed to be the result of maturing vegetation, according to the EPA report.

That study also showed that the green roof reduced peak runoff rates by 95% during an intense storm. Because of their benefits in controlling stormwater, Portland has approved green roofs as a technique to meet stormwater management requirements for new development and redevelopment projects.

Plants and growing medium on a green roof not only retain and delay the release of stormwater but also act as a filter. A 2005 Canadian report cited by the EPA synthesized existing studies that note green roofs can bind and retain significant levels of pollutants, with one study finding that green roofs could remove up to 95% of cadmium, copper, and lead from stormwater runoff.

However, the same study found increased concentrations of nitrogen and phosphorus, attributable to certain compost materials in the roof substrate. Other research shows that over time, those levels decrease as plants mature.

Until recently, Dr. Mike Hardin, a water resources engineer with Geosyntec—a consulting and engineering firm for private and public sector clients seeking assistance with environmental and civil infrastructure needs—was involved in green roof research at the Stormwater Management Academy, where he served as a research associate until he earned his Ph.D. in environmental engineering. Hardin’s research focused on green roof stormwater-related water quantity and quality. He managed the UCF field lab, which is funded by a Florida Department of Transportation grant and performs research on stormwater best management practices (BMPs) including green roofs, as well as erosion and sediment control.

Hardin’s research on a UCF demonstration project with a green roof and control roof found that the concentration for nitrate from the green roof was lower than that from the control roof; there was 0.1 milligram per liter of nitrate coming off of the green roof in contrast to the 0.4 milligram per liter coming off the control roof.

“Combustion processes release nitrogen oxides into the atmosphere, and then those can precipitate down onto the roof and accumulate during dry periods,” notes Hardin. “The next time it rains, it washes all of that off, and it starts to build up again.”

In examining phosphorus, which is a limiting nutrient for plant growth in most of Florida’s surface water bodies, Hardin and his team found the concentration of phosphorus coming off the green roof was higher. “However, once you take into account the volume reduction that you get from your green roof, the mass was actually significantly less coming off the green roof compared to a control roof,” he says. “The same for nitrogen—as soon as we took into account the volume reduction, then we had a very significant reduction in the mass that comes off these systems.

“Sometimes people can get hung up on what concentration you’re discharging, but quite frankly mass is more important,” he adds. “The old adage ‘the solution to pollution is dilution’ is not true. You can have a large volume of water that has a low concentration, and it very well could have a larger mass component of that pollutant than a smaller volume of water with a much higher concentration.”

Green roof at the University of Central Florida

UCF researchers found that anytime there had been volume reduction, what came off the green roof was equivalent to or much less than what came from the control roof.

“We saw reductions for our system,” says Hardin. “Our hydrologic efficiency was about 80% for our system, so 80% of the stormwater runoff was prevented from leaving our system on an average annual basis. Similarly, our mass reductions would be about 80%. For phosphorus, it was about the same because the concentrations were very close for the control roof and the green roof, but for nitrogen, it was much, much lower.”

UCF researchers also examined various types of growth media that could potentially hold more nutrients on the roof and filter the water before it discharges and leaves the system. “We ended up developing a pollution control layer, which would be either a one- or two- inch layer of specialized media that we would put on the roof, and it had a high affinity for phosphorus,” says Hardin. “When we looked at a comparison for our green roof that had this pollution control media and a green roof that did not, we saw a substantial reduction.”

The green roof without the pollution control layer had a concentration of orthophosphate of about 0.7 milligram per liter. The concentration was reduced to about 0.3 milligram per liter for the green roof with Bold & Gold, a biosorption activated media (BAM) developed for stormwater filtration at UCF and now used for other forms of stormwater runoff.

“Plants themselves also do a good job of taking out nitrogen and phosphorus,” says Hardin. “Those are macronutrients that they need for growth and cell synthesis anyway.”

Increased water quality comes through design, Hardin says. “In Florida, we design them with a cistern or some method to capture the runoff from the roof and then use that water for some other application, be it re-irrigation of the green roof, irrigation of ground-level landscaping, or even toilet flushing or graywater uses,” he explains. “Just being able to reduce that volume further provides a significant benefit in regard to both water-quality and water-quantity benefits.”

In addition to improved water quality through filtration, green roofs also offer the downstream benefit of downsizing or eliminating traditional stormwater management methods such as pipe storage, cisterns, and vaults.

The Ford Motor Company’s large green roof on its Rouge River plant in Michigan helped save about $2 million in stormwater mitigation costs because the reduced volume of runoff from its factory reduced the size of ground-level stormwater treatment that was needed, Hardin says.

Another benefit is longer lifespan for roofs, which some estimates place at up to 50 years and beyond, Hardin adds. That offers financial benefits to building owners. “A more substantial way in which these membranes can degrade is through thermal expansion and contraction as materials heat up and cool down,” he says. “This puts a lot of stress on the material and can degrade it over time.”

Another UCF green roof demonstration project involved research by the Florida Solar Energy Center at UCF, which conducted a temperature study on the roofs.

One study showed a 45% reduction in heat flux, an indication of the thermal performance or the efficiency for cooling purposes, compared to a high-albedo roof, an Energy Star-rated cool roof.

“That doesn’t translate to a direct 45% reduction in electrical costs or heating and cooling costs,” says Hardin. “A building can gain and lose heat in many different ways, one of which is through the roof. Other ways would be through the walls, windows, and doors, so if you’re looking at a high-rise building, that savings is going to be insignificant. However, if you’re looking at a big box store, a majority of its area is roof area. A green roof could be a significant savings to them.”

According to the EPA report, too, when green roofs are wet, they absorb and store large amounts of heat, reducing temperature fluctuations. When dry, they act as an insulator, decreasing the flow of heat through the roof, reducing the cooling energyneeded to reduce building interior temperatures. In the winter, the insulating effect means less heat from inside of the building is lost through the roof, reducing heating needs.

For example, Chicago has estimated its City Hall green roof project could provide cooling savings of approximately 9,270 KWh per year and heating savings of 740 million BTUs, translating to into annual, building-level energy savings of about $3,600.

Reduced energy demand from green roofs reduces air pollution and greenhouse gas emissions associated with energy production, the EPA report points out.

Green roofs have also been used to reintroduce habitat to areas that desperately need it, says Hayden. In dense urban areas, green spaces are at a premium. Properly selected plant materials can provide nesting habitat to birds and other fauna.

Additionally, benefits come through green roofs serving as horticultural therapy settings for hospitals and health care facilities, as well as urban agriculture sites for food and honey production. Hardin says some hotels save thousands of dollars each year growing their own vegetables and herbs on the roof.

“In denser urban environments, green spaces often can promote higher rents and property values for the owners,” he notes.

Hardin says some studies show hotels that have rooms with a view of green space or green roofs can charge more than for a room with a view of a regular rooftop with mechanical equipment on top of it. “There are a couple of ways you get that money back in energy savings and roof life,” he adds. “Essentially in Florida, you have to re-roof every 15 to 20 years. In reality, it’s more like 10 to 15. The first time you would re-roof your conventional roof, you just paid for your green roof.”

Costs

Green roof costs depend on such factors as growing media, type of roofing membrane, drainage systems, plants, and other components. “The typical cost for an extensive green roof is about $22 per square foot,” says Hardin. “This includes the membrane price, which is about $9 per square foot of that cost.”

Experts agree that while startup costs for a green roof exceed those of a conventional roof, its long-term life cycle benefits in longer roof life and reduced costs in stormwater mitigation, energy, and public health help derive a return on the investment.

The largest green roof in Quebec features 80,000 square feet of vegetal i.D.’s Hydropack atop a bus garage in Montreal

Site Characteristics

Certain areas lend themselves better to green roofs. In urban regions with large areas of impervious cover, green roofs offer opportunities to add more vegetation.

Low- to medium-rise buildings such as Ford’s Dearborn Truck Plant in Michigan, which has a large roof area, are ideal for the goals of saving energy and managing stormwater. “In urban areas, there are a lot of parcels that were developed before modern stormwater regulation, so when those parcels get sold and someone wants to redevelop them, they now have to meet current stormwater regulations,” notes Hardin. “You’re dealing with an area that is very impervious due to development, but also land is very expensive, so if you have to build a two- or a three-acre stormwater pond, that’s not going to work, not to mention the space just may not be available at all.”

Renovating with green roofs is becoming increasingly popular, with low-sloped residential and commercial buildings with large roof areas presenting opportunities for installations with minimal disruptions.

In some cases, the only choice in meeting modern stormwater regulations is using LID measures such as green roofs, pervious pavements, and water harvesting, notes Hardin.

In a rural area, though, it might not make sense from a cost perspective to do a green roof, Hardin points out. “It might be less expensive to buy additional land and treat your water with the conventional means of digging a retention or detention pond,” he adds.

Installation

The evolution of a green roof as a stormwater BMP “means that these roofs must be properly designed to provide long-term performance as a green space and as a stormwater BMP,” says Hayden.

“Garden roofs are actually a variant of the protected membrane roof concept,” he says. “In this concept, the membrane is installed directly to the deck and the insulation is placed over the membrane. Ballast, such as stone or pavers, is then installed to secure the insulation from moving. This is the preferred roofing technique for many agencies including the GSA, as the membrane is not exposed to mechanical or environmental damage. Instead of ballast stone or pavers, the growing media in a Garden Roof provides the necessary ballasting function.”

In installing a green roof, building owners need to ensure the structure can support the green roof when fully saturated and meet code requirements for snow and wind loads, according to the EPA report.

For example, American Hydrotech’s Garden Roof installation typically begins with a concrete deck forming the structural element in the roof. Hydrotech’s MM6125 waterproofing membrane is installed directly to the structural deck in a thick monolithic and seamless rubberized asphalt layer to protect the building from water infiltration. A layer is placed over the membrane, which provides the initial protection to the membrane from physical damage during subsequent construction activities.

The EPA report also recommends a vapor layer that resists passage of moisture through the ceiling.

Thermal insulation is recommended above or below the membrane as the insulation value of the growing medium in a green roof increases as the moisture content decreases. A cover board provides protection, separation, and support for the roofing membrane.

A root barrier is recommended to be placed on top of the membrane to protect it from aggressive plant roots that may penetrate the waterproofing barrier and cause leaks.

Insulation is then placed over the root barrier. “American Hydrotech uses Dow Chemical’s Styrofoam-brand insulation,” says Hayden. “Styrofoam is the best insulation for use in our roofs because it is does not absorb water like other insulation types.”

Usually, multiple layers of Styrofoam are used to achieve the desired total R-value needed by the building, he adds.

After the layers of insulation are installed, American Hydrotech’s Gardendrain water retention layer is installed.

“This is a synthetic ‘waffle board’ sheet of various thicknesses designed to retain water, provide drainage, and provide aeration of the media. It comes in thicknesses of 15, 30, and 50 millimeters to address a wide variety of project conditions and objectives,” says Hayden.

American Hydrotech uses Systemfilter to separate the Gardendrain from the LiteTop growing media above. “This Systemfilter allows for water and air transfer and keeps the fines in the LiteTop media from filtering into the lower assembly layers,” says Hayden.

Next, American Hydrotech installs LiteTop to the depth needed for the particular needs of the roof.

Growing media choices depend largely on the vegetation. The choice is also based on whether the roof is extensive or intensive, the building design, the local climate, available sunlight, and irrigation requirements, among other factors.

Plant materials are installed after the growing media. “These can include sedum cuttings and plugs as well as a wide variety of perennial plants that have been selected for use on green roofs,” says Hayden.

Low-growing plants are typically used for extensive roofs. Because intensive roofs are more high profile and often intended for public enjoyment, a greater variety of plants may be used, including edibles.

Typically, hardy perennials are selected for extensive green roofs. Succulents, such as sedums, also adapt well in green roof environments.

Sedum-based green roofs “rely on the perpetual nature of the vegetation to thrive,” notes Hayden. “Monocultures—single-species plantings—are not encouraged, but rather a broad spectrum of sedum and perennial species are used in extensive roofs so that the wide varieties of roof conditions can be accommodated.”

Hardin likes using PVC or thermoplastic membranes because they are impermeable to roots, he says. “Whenever you waterproof a roof, you have to leak-test it. However, there is no way to test how well it is protected against plants with strong roots.”

Hardin then uses a protection mat on top the membrane, which he says is akin to felt with a plastic net in the middle. “It protects the membrane during roof construction and after from anything that might have sharp edges, such as construction tools,” he says.

A drainage layer helps excess water from the growing medium flow to the roof drain. “There are so many options for the drainage layer; washed gravel works great,” says Hardin. “Usually we use a larger-sized expanded clay, which is very lightweight. Expanded clay is usually around 45 pounds per cubic foot, and soils are about 110 or 120 pounds per cubic foot. There are a lot of manufactured materials you could use.”

A filter membrane is usually a nonwoven geotextile, allowing excess water from the growing medium to flow out and prevent fine particles from washing away and clogging the roof drain. “While we do want to hold more water on the roof, we don’t want that water sitting on the membrane,” says Hardin. “Once it gets through the media, we want it to drain off the roof rapidly.”

On top of the fabric layer, Hardin likes to use Bold & Gold as a pollution control layer.

He says irrigation is needed for some green roofs, especially those in climates like Florida’s. He prefers drip irrigation for its ability to precisely deliver water to where it’s needed.

Maintenance

“One of the biggest myths in the green roof industry starts with the statement ‘green roofs do not require maintenance,'” notes Hayden, adding that American Hydrotech has a maintenance protocol that can be adjusted to address the specific green roof assembly and vegetation type.

“Maintenance begins at installation in order to fully establish the vegetation on the roof,” he says. “A good source of water is needed for establishment. Many owners have opted for fully automatic irrigation systems to protect their investment. Even when not used regularly, the irrigation systems can stand ready to add vitally needed moisture when natural rainfall amounts fall short. Once established, green roofs require occasional maintenance activities, mostly related to removal of the occasional weed and to check the condition of the roof flashings and drainage structures.”

Other typical maintenance activities include a plant inspection, growing media replacement, debris and trash removal, weed removal, testing the growing media, replanting, fertilizing, pest control, gutter cleaning, checking irrigation systems, and inspection of the zones where there is no vegetation.

“You need to make sure that no birds drop anything that you don’t want growing on your roof,” adds Hardin. “You have to pull invasive plants from time to time.”

Fertilization depends on plants’ robustness, says Hardin. “Usually at the start of a roof, you want to fertilize it a couple of times to get everything going,” he says. “I’ve seen some projects where they fertilize only a couple of times and they don’t have to worry about it, and other ones where they had to fertilize for the first two years before they didn’t need to anymore. Other than that, it’s specific to the owner and what they want.”

Essentially, maintenance depends on what the property owners want, says Hardin. “Some people want something that’s manicured, and other people are OK with a more wild and natural look,” he says. “Our take on it when we were doing the green roof at the UCF student union is that we’ll plant the plants where we like to see them and then we’ll let them do their thing. One of the interesting things we saw is that the plants would migrate across the roof and then they would end up where they prefer to be.”

Fire Safety

The EPA report points out that green roofs, when saturated with water, can slow the spread of a fire. To ensure fire safety, plant selection should avoid grasses and plants that dry up in the summer, as well as growing media low in organic material content. Fire breaks of 2-foot widths of concrete or gravel at 130-foot intervals should be constructed on the roof.

Installing Hydropack green roof trays on a

Shenandoah University rooftop

Academic Research

In addition to UCF, an increasing number of universities are studying green roof technologies. Others include Michigan State University, which began with a Green Roof Research program to assist with the design and study of Ford’s Rouge Plant and has since expanded. Penn State University has a Center for Green Roof Research program. North Carolina State University has green roof test sites. The British Columbia Institute of Technology’s Centre for the Advancement of Green Roof Technology collaborates with industry to support green roof initiatives.

A growing number of cities have begun initiatives to promote green roof use for stormwater mitigation, as well as for reducing urban heat islands and for urban ecosystem enhancement.

Florida’s first green roof was built in 2003 in Bonita Bay. Although the project involved a respected consultant from the north who had been doing green roofs for many years, the otherwise successful project struggled because it was installed withgrowing media from the north, which does not do well in Florida, Hardin notes.

“Florida is unique in the sense that it gets very, very hot,” points out Hardin. “We have prolonged periods of drought. Green roofs without irrigation don’t work well down here. Also, you can’t use a dark-color or shale-based growth medium. It just burns the plants.”

Another view of the Montreal bus garage roof

Within a year of the state’s first green roof construction, the UCF Stormwater Management Academy began green roof research. Researchers constructed a demonstration project green roof and a control roof atop the newly expanded student union.

“It gave us an opportunity to look at the advantages of stormwater volume reduction as well as water-quality improvement, if there was any,” says Hardin. “Some research suggests that green roofs may be polluters in the sense of discharging more nutrients than a control roof.”

That makes sense from the presence of a significant amount of organic material on top of a roof that normally wouldn’t be there, he adds.

In the UCF demonstration project, the green roof and the conventional control roof each covered 1,600 square feet. Each section had dedicated drains. Two cisterns were installed at ground level to capture water from the green roof and the control roof.

“That allowed us to monitor water quantity, but also gave us an opportunity to measure water quality,” notes Hardin.

In the meantime, Hardin constructed 16 different small experimental chambers by the stormwater field lab to allow researchers to examine different media types. “We wanted to look at a pollution control media that would help control the release of nutrients from a green roof—something that would help hold the nutrients up on the roof so the plants could use them as opposed to letting the wash out with the runoff,” says Hardin.

One of the findings: Florida roofs need irrigation due to the state’s periods of extended drought. “We have drought-tolerant plants in Florida; however, those plants typically have a tap root that would grow straight into the water table, which of course isn’t available on top of a roof,” notes Hardin.

UCF researchers looked at beach community plants, which grow in nutrient-poor, very well-draining soils in high temperatures and rough conditions. The plants performed well, especially when irrigation was used.

“Irrigation also helped us get rid of additional water since we were capturing our runoff anyway in a cistern,” says Hardin.

The next move was to pump stormwater back up on the roof and use it for irrigation, further reducing the amount of stormwater runoff that left the system.

“That resulted in a mass reduction of nutrients; concentration times volume is mass,” points out Hardin. “We were able to show a very significant mass reduction for nitrogen and phosphorous when using a cistern. We were also able to show a very significant volume reduction.”

As part of his research, Hardin developed a hydrologic model that predicts the hydrologic efficiency of a green roof based on cistern size and green roof characteristics, such as media depth, available water, and geographic location. “Rainfall patterns vary throughout the state,” says Hardin. “We developed this model and figured out the variables that contribute to a successful green roof project in the state of Florida.

Then we duplicated this across the state on a number of projects.”

Among those projects:

- The Starbucks green roof at Walt Disney World’s Downtown Disney in Orlando. “Starbucks is always very conscious of their image to their customers,” notes Hardin. “They want to be ‘green’ and be viewed as a progressive company that cares about people and the environment. For them, the driving factor was doing an environmental stewardship projects. Also, in doing it, they lead the way for other companies to follow.” Hardin calls the installation “unbelievable” and “sharp-looking.” The designer is Kevin Songer of MetroVerde. “He really knows his plants very well. He had a great idea about backlighting the plants, so he ran green LED lights on top of the roof; at night, those lights shine up under the plants and that roof just glows. It’s truly incredible.”

- Headquarters Honda in Clermont, FL, which installed a green roof in 2012. “That roof is a cool project,” notes Hardin. “They have a little more than 5,000 square feet of green roof. They also have a lot of photovoltaics up on the roof as well for solar power. They’re capturing the water that comes off the roof to wash vehicles and using it for irrigation.” The headquarters, a LEED Platinum certified building, also has pervious pavement onsite. “It’s a super-efficient building, really remarkable,” notes Hardin.

- Florida’s largest green roof covers 33,000 square feet on top of the Escambia County One Stop Permitting Center in Pensacola, constructed in 2010. “They also have a pervious concrete parking lot,” notes Hardin. “That’s a very green building. Water quality and water quantity were the driving factors for doing it. All of these people in the construction industry and designers need to go there to pull their permits, so they thought what better way to showcase this kind of technology than in a building where these people are going to be coming to visit fairly regularly anyway. They wanted to have a demonstration for the green roof and a demonstration for the pervious pavements.”