Peat: A Natural Solution for Stormwater Compliance

Mark Twain said that there is no such thing as a new idea. Instead, we rearrange old ideas in a sort of ‘mental kaleidoscope’ to create new concepts and innovations. The idea of using peat for water treatment certainly fits into Twain’s paradigm.

Peat has been used by Mother Nature for millennia to clean water. Wetlands are natural environmental filters because of the peaty, organic soils common to many shallow water systems.

In recent decades, we’ve turned the kaleidoscope to apply peat’s natural sorption capacity to modern water treatment applications — out of the wetlands and into the built environment.

Why Peat?

Peat is poorly decomposed plant matter that has accumulated in low-lying, wet areas where the summers are warm enough to encourage vigorous vegetative growth and the winters are cold enough to hamper decomposition. Peat is considered to be a slowly-renewing renewable resource, accumulating at a ballpark rate of 1 mm per year in depth.

As it forms, peat develops a natural affinity for dissolved constituents found in ground and surface water. For example, if the groundwater is rich in manganese, peat deposits can act as a filter to sorb the metal and produce water with less manganese.

The same principles can be applied when using peat to filter other impurities in water that has been impacted by human activity. Historically, treating stormwater or industrial water with peat has involved wetland systems that capture and treat water with peat in a passive treatment bed.

Not All Peat Is Created Equal

Peat is classified in multiple ways, starting with the parent plant material that gives rise to the peat deposit. If the parent plant material is grasses, reeds, sedges and other vascular plants, the peat is often called reed-sedge peat. In those areas where mosses thrive in nutrient-poor environments, the peat may be Sphagnum peat. Reed-sedge and Sphagnum peat are different from each other both physically and chemically, which means they don’t behave the same way in water treatment applications.

Reed-sedge peat is primed to attract and bond with dissolved heavy metals from human activity, including lead, cadmium, copper and zinc. Peat forms strong natural bonds with these metals through a process called adsorption, making it very effective in industrial and stormwater treatment.

Sphagnum peat also has an affinity for dissolved metal cations, but its capacity is not as great, so it is a secondary choice for heavy metal remediation. On the other hand, Sphagnum peat is able to absorb more than 70 percent of its weight in oils, making it an ideal choice for removing hydrocarbons from environmentally sensitive areas.

Natural Environmental Remediation

The use of Sphagnum peat booms to treat oil spills is well-known, and Sphagnum-based products such as floor cleaner and spill pads are readily available. Sphagnum peat, used in hydrocarbon remediation and from a reputable seller, is a gentle, cost-effective way to remediate oil spills.

Reed-sedge peat has a natural affinity to bond heavy metals, making it ideal for natural water remediation. But raw peat is quite impervious to flow and requires large amounts of sand to improve hydraulic connectivity. Dried peat is dusty and inconsistent, but when processed into a granular form, transforms into a powerful medium for natural water treatment.

Mines, foundries and commercial buildings are held to strict water quality standards, often requiring treatment or remediation before water can be discharged. Granular reed-sedge peat has been used successfully in both passive and active water treatment systems in industrial applications across the United States.

Mine Water Management, Naturally

The mining industry is often painted as anti-environment, but that is an unfair characterization. In the U.S., mine water must be treated to remove contaminants, including trace metals, before it can be discharged into the environment. While conventional treatment is labor intensive and expensive, peat-based sorption materials have proven to be a less expensive and easy-to-deploy treatment alternative.

An iron mine in Minnesota used granular peat in a semi-active treatment system and recorded an average removal of 75 percent for suspended copper and 60 percent for dissolved copper while reducing the size, complexity and operating cost of the treatment system. At a base metal mine, lead removal was greater than 99 percent and operating costs were well within budget. Those are both solid wins for peat and for the mining industry.

Simple, Effective Treatment Solutions

A Washington-based foundry needed to reduce copper in its stormwater to comply with its stormwater permit. A traditional active treatment system came with a price tag of $60-100K, which was more than the foundry could afford to implement, operate or maintain. They needed a less expensive and lower maintenance passive treatment system, and they found it in granular peat sorption media.

Since all the foundry’s stormwater flowed into a single drain system, a flowthrough treatment system using simple peat-filled filter socks was placed in the drain line. The peat helped drop copper concentrations below the benchmark value and the foundry has been in compliance ever since.

Rethinking Roof Runoff

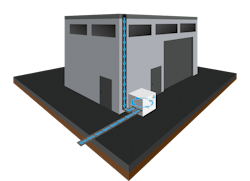

An industrial facility in the Pacific Northwest was out of compliance with its stormwater permit and needed a solution to complement its existing end-of-pipe treatment system. After isolating the roof area that contributed most heavily to zinc loading, facility managers installed upflow downspout filters filled with a bed of granular peat media.

The filters treated roof runoff every time it rained, effectively dropping zinc concentrations entering the end-of-pipe treatment system by 50 percent and successfully bringing the facility back into compliance.

Out with the Old, In with the Natural

Clean water is a precious commodity. It is critical that we protect our water supply so that it can be recycled indefinitely. As we turn Twain’s kaleidoscope to find new solutions to age-old challenges, looking for ways to use the resources we have on hand to resolve complex environmental issues, industry keeps returning to peat.

When used judiciously and harvested in a responsible manner, the world’s peat supply can provide significant benefits. Treating environmental contamination with non-toxic, natural peat is a prime example of a best use for natural resources. SW

About the Author: Peggy Jones is the VP of sales and research at American Peat Technology (APT). Peggy started at APT nearly 15 years ago and now oversees product development and customer relationships.

Published in Stormwater magazine, November 2021.

About the Author

Peggy Jones

Peggy Jones is vice president of sales and research for American Peat Technology in Aitkin, MN.